Ever since the discovery of graphene extraction last 2004, multiple companies invest in innovating their products. After all, graphene has tons of excellent traits that can push forward different industries in the world. More specifically, graphene remains the thinnest material, only having a layer of atoms in a honeycomb structure. Despite its size, researchers proved that it has a strength 200 times greater than steel while still providing flexibility. Not only that, but it also offers high thermal and electric conductivity and tolerance. Even as an ingredient for composite materials, graphene can still provide those top-notch traits. And with those properties the material has, experts predict graphene to impact the same as the Industrial Revolution. With several industries applying this technology, companies that produce rubbers have considering having graphene in their products.

The applications of graphene to rubber-related products have existed for more than years now. Specifically, automobile companies have already adapted graphene technology to produce tires. However, people can only witness its application mostly in Asian Countries, but the west has started its research. With this large industry, business experts expect to grow up to 2.5 billion graphene tires produced by 2022.

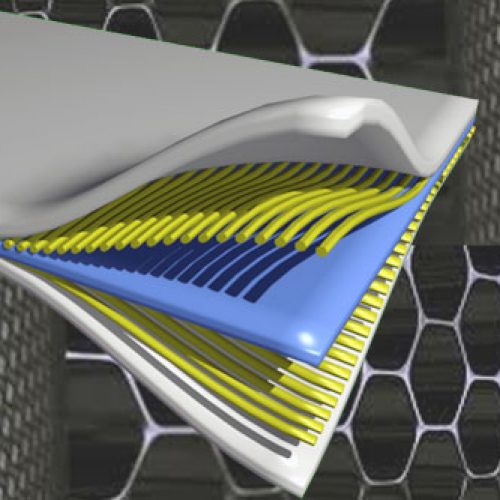

Worldwide, tire makers utilize graphene inside tire tracks, dividers, and inward linings to make tires lighter. Likewise, it can give a better grasp and decrease moving opposition. Fillers are regularly scattered in a flexible framework. The high surface region, high angle proportion advances higher dynamic-mechanical properties of elastic mixtures and empowers elastic composites' scraped spot obstruction significantly.

Since graphene has a strength 200 times more than steel, that property can help rubbers have more endurance. With its power, it can provide more flexibility to the material, thus also increasing the stretchability and elasticity. With all these properties adding up, companies can now create much more durable rubber to release in the market.

However, graphene can improve not only the mechanical traits of rubbers but also its heat tolerance. With a metal-quasi being added to rubber, the thermal resistance can significantly increase. Likewise, the flame retardancy will improve as well, making the material slower to burn.

Nonetheless, most of the said property can reflect on the construction industry, providing better materials. For example, companies can create better rubber bearings for buildings through the use of graphene. Not only that, but they can also produce graphene sealing products.

With the application of graphene in a tire, manufacturers can preserve multiple aspects. For example, graphene atom structure provides a strong coating for tires that do not allow corrosion. That makes the tire wear off not as easy and not as fast as before. Moreover, it helps extend the tire's life span, which means that users do not need to replace their tires that often.

Furthermore, it helps drivers to handle the vehicles better when travelling. The friction resistance it gives assists the drivers to calculate the braking distance. Also, it provides better grips for the tire, especially when turning the vehicles in a direction.

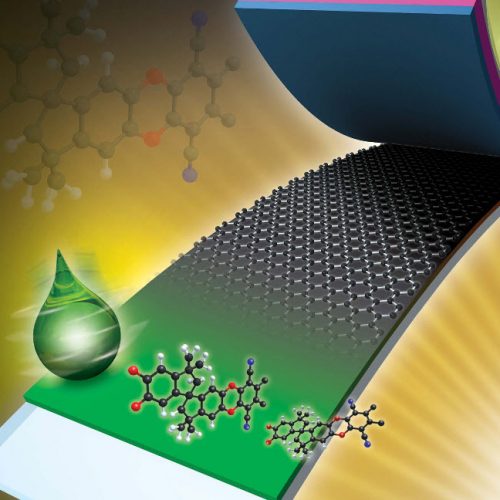

The direct incorporation of graphene into diverse materials demonstrates the sustainability potential of graphene. It has revealed that the incorporation of graphene into numerous materials is possible. Combining graphene with other materials construct sustainable products in the past years. Fortunately, green graphene production methods are also available. Besides electronics, sports, and footwear, plastics is another field where graphene can bring more sustainability. Recycling is in place for renewing plastics across the world. However, there are sometimes significant issues, as recycled plastics appear to have worse mechanical properties than the original plastic, minimizing their use.

Thus, a range of different companies, including TLC Products, incorporates graphene into different plastics varieties. By doing so, there will be a development of plastics with powerful mechanical properties. To enhance the sustainability of the plastics industry, the use of graphene will be effective. Without significantly increasing the cost, the creation of more durable plastics will be made possible.

Thanks to several pieces of research, graphene-enhanced products can be a key to a more sustainable environment. Today, plastic composites can be combined with graphene, giving the product new and improved properties. Indeed, graphene will transform and improve our lives in different ways.

Overall, there is a capacity for producing more products without toxic chemicals. Because of graphene, more sustainable, environmental, and cost-effective innovations are made possible. Also, graphene tends to take a long time to re-enter the CO2 phase compared to other carbon products. This fact is another aspect wherein graphene can have a positive environmental effect.

Fill the form below: